Quality through consultation, design, production, sampling, measurement and service

We deliver injection moulds ready for series production with initial sample test reports.

Our services revolving around tools

Simulation:

Simulation:

We can carry out injection moulding simulations internally with our complete package from SOLIDWORKS Plastics.

Rheological and thermodynamic predictions can be provided for both crystallising and networking plastics with regard to filling and warpage.

Technology centre:

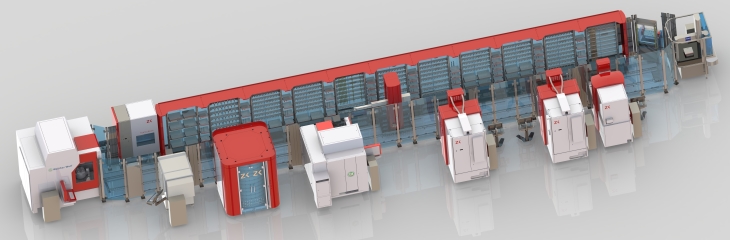

An Arburg 520C (2,000 kN) and an Arburg 320C (600 kN) are available for internal sampling.

Small series are also possible on request.

Measurements:

It is possible to generate initial sample test reports and series measurements.

There are 5 coordinate measuring machines from Zeiss, 2 GOM systems, a multi-sensor measuring machine and a CT scanner available to this purpose.

Reverse engineering: Should you not have any or only unreliable design data at your disposal, we can thus offer you reusable CAD data through measurement and restoration.

External tools:

Through many years of experience, we are now also capable of offering maintenance, replacement parts, repairs and changes for external tools. This is also possible without existing data.

Special features:

ECM tools, Duroplast tools, high temperature tools, insert technology, multi-component tools, high-cavity tools, cartridge tools, set-up time reduction for turntable machines with positioning units, design of tool families

Service:

We offer you training seminars, commissioning and process accompaniment for tooling and injection moulding technology.

This also outside of Germany on request.

Fast and precise redimensioning

In close cooperation between our technical centre and our measurement laboratory, we can redimension your injection moulding tools according to your wishes and quickly adjust them.

With corrective grinding for dimensional and mould technology improvements, we can make your injection moulding tool ready for series production in the shortest time possible.